WE OPTIMIZE

YOUR PROCESSES.

Technology from one source.

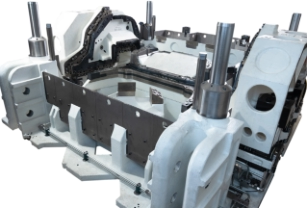

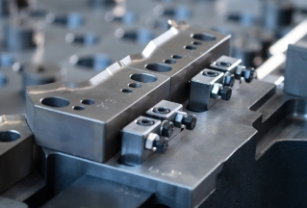

Trimming Press. Trimming Tool. Quench Tank.

Synergies that simply work:

As a tool manufacturer, Aulbach Entgratungstechnik is one of the leading companies for trimming tools

and systems and has specialized in the design and manufacture of tools of all levels of dificulty since the

company was founded.

Together with the company abk Pressenbau, which focuses on the development and manufacture of

hydraulic trimming presses and peripherals for the foundry industry as well as spotting presses for mold

making, we other our customers turnkey solutions from a single source.

Thanks to its technical know-how and many years of experience, abk has developed a standardized and

almost fully equipped trimming press for the deburring of ultralarge die-cast parts aka MEGA/GIGAcasting,

adapted to the requirements of the trimming tool. The appropriate quench tank in various sizes rounds off

the delivery portfolio for MEGA/GIGAcasting die-casting cells.

These machines are built in series in Mömlingen according to the production standard, which means that

the customer has a great benefit in terms of delivery capability.

Together we are currently technology and market leaders in terms of dimension and process experience.

Experience. Quality. Process reliability.

About us

About us

Beginnen erst wen

n man auf Play kli

ckt

abk Insights

Assembly

Production

Design and Engineering

Service

abk full automatic tool change

The features

The features

T

ext wird n

ochma

l überarb

eit

et

TURNKEY TRIMMING SOLUTIONS.

THINK BIG. PRODUCE BIG.

KEEP COSTS LOW.

Fast reliable tool change

A coordinated, fully automated tool

changing concept, consisting of a tool

feeder and hydraulic clamping system,

ensures short set-up time.

Flash disposal

A coordinated concept consisting of a large

press opening and openings and discharge

plates in the lower part of the tool ensure

optimal disposal of the gate system,

overflows and vacuum channels.

Breaking of gating system for process-

reliable waste disposal

Reduction of tension in the casting by

removing the gate system connection

directly after the casting process using

special break off knives.

High quality of trimming edge &

repeatability thanks to adjustable knives

A defined contour cut, based on 3D data of

casting, for material thicknesses up to 5mm

ensures high repeatability in the process.

TRADITIONAL

TECHNOLOGY REDEFINED.

Reasons for deburring with a press and tools

The benefits

The benefits

Short cycle times

1

High repeatability

2

High cutting quality thanks to

adjustable knives

3

Reliable removal of gating system,

overflows, vacuum channels and

burrs through the press opening

4

Reduction of tension through direct

trimming after casting

5

The press/tool concept is

coordinated

6

Fast and safe tool change

7

AULBACH AUTOMATION GMBH

abk Pressenbau

Am Amorbach 3

DE-63853 Mömlingen

+49 6022 / 264 76-0

info@abk-pressenbau.de

www.abk-pressenbau.de

TURNKEY TRIMMING SOLUTIONS.

THINK BIG. PRODUCE BIG.

KEEP COSTS LOW.

AULBACH Entgratungstechnik GMBH

Am Kreuzfeldring 5

DE-63820 Elsenfeld

+49 6022 / 2088-0

info@aulbach-com.de

www.aulbach-com.de