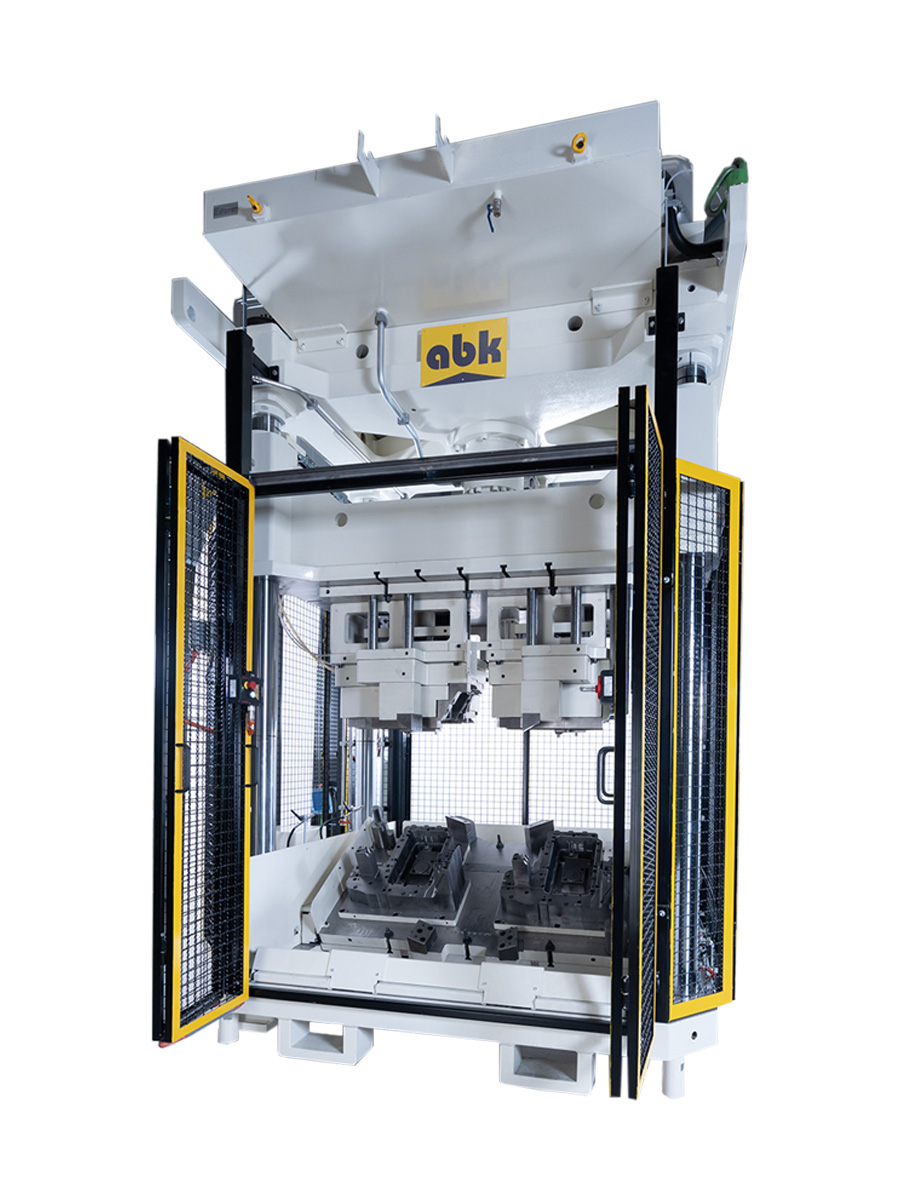

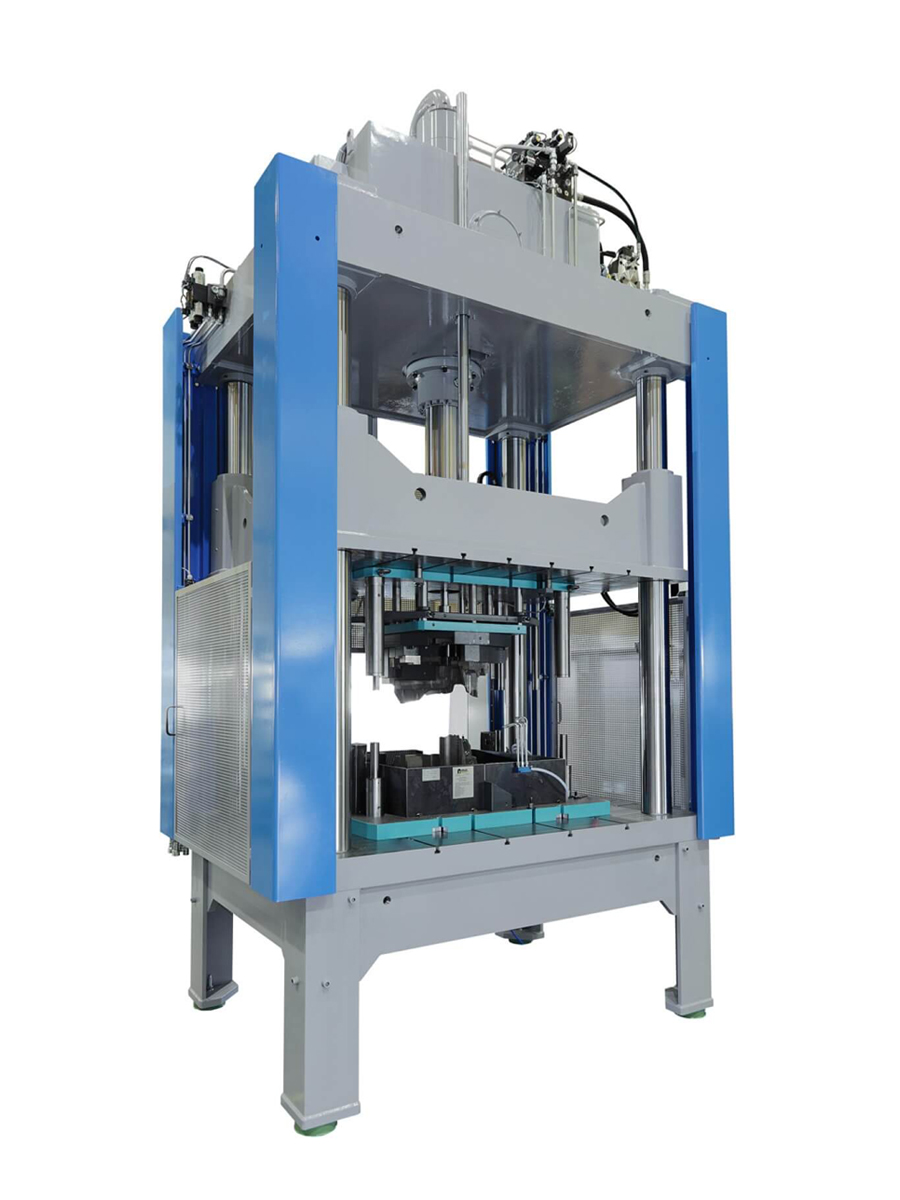

Spotting presses from ABK enable safe and precise adjustment, maintenance, and commissioning of tools directly under press force. The controlled closing process allows forming and cutting tools to be reliably checked for fit accuracy and material contact – without any risk to the tool or the operator.

Our presses are designed for maximum safety, optimal accessibility, and ergonomic operation. Each machine can be precisely adapted to individual requirements – in size, press force, and equipment configuration.

Ensures safe spotting without damaging sensitive tool surfaces

Ideal for precise tool alignment and fit verification

Generous working areas with optional sliding table or rotary table

Light curtain, two-hand control, and emergency stop for maximum protection

Touchscreen operation panel with freely programmable spotting cycles

Built for daily use in toolmaking and maintenance environments

Simple and Efficient

Simple and Efficient

Simple and Efficient

Simple and Efficient

Simple and Efficient

Simple and Efficient