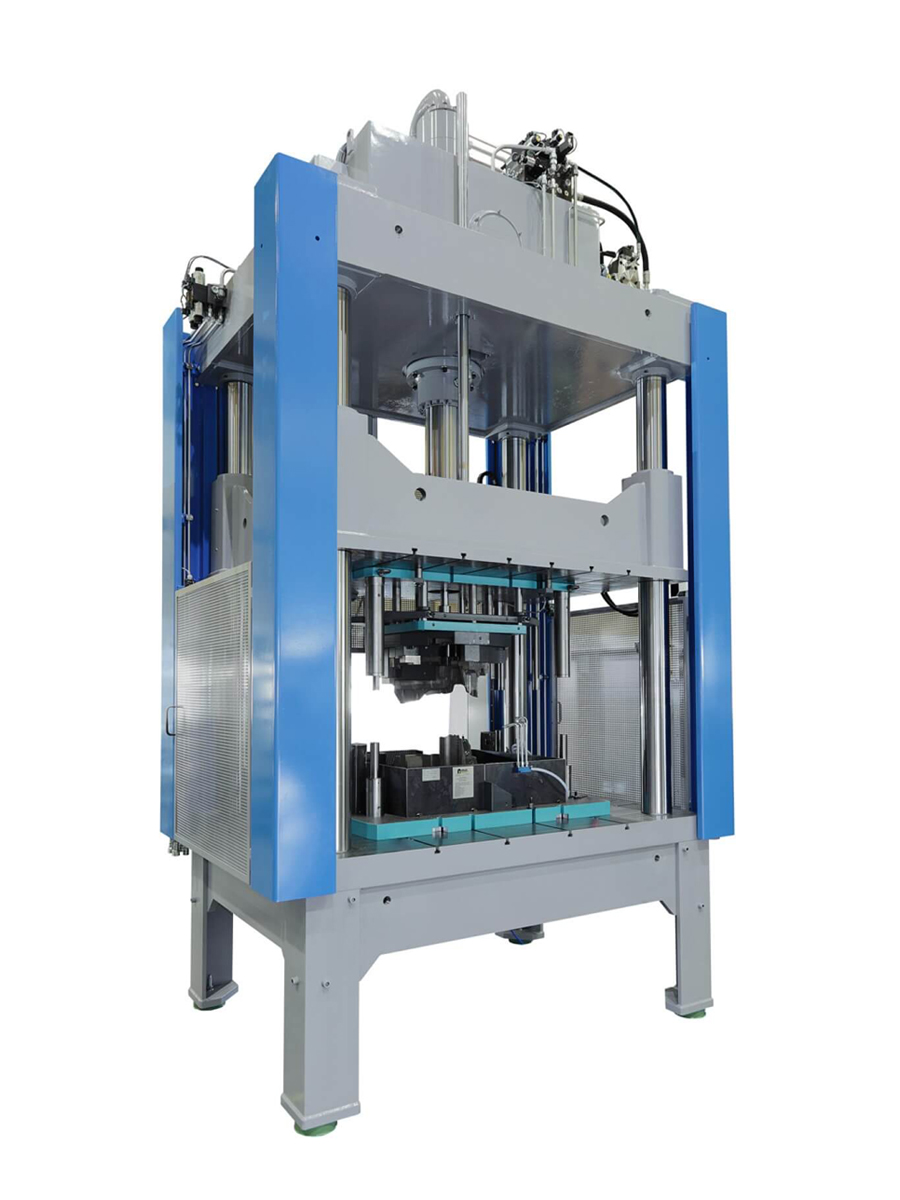

The tilting table presses from abk are compact in design, efficient in operation, and perfectly suited for automated deburring applications. The integrated, low-maintenance rotary drive with position control enables precise movements and flexible table positioning – tailored to your process requirements.

Thanks to the proven abk column guide without central lubrication and maintenance-free components, this press series is designed for long-lasting and energy-efficient continuous operation.

The scrapers can also be replaced directly in the assembled state if required – without disassembling the columns. This saves time, reduces maintenance costs, and ensures maximum machine availability.

The compact rotary drive with integrated position control is another key feature of this series. In combination with intelligent control technology, it ensures short cycle times, high flexibility, and reliable process management.

With position control – low-maintenance and freely programmable

Achieved through rotation of the lower table

Casting parts can be loaded and unloaded ergonomically from the outside

Designed according to component weight, cycle time, and installation conditions

High integration capability

Without central lubrication – low wear and friction

Simple and Efficient

Simple and Efficient

Simple and Efficient

Simple and Efficient

Simple and Efficient

Simple and Efficient