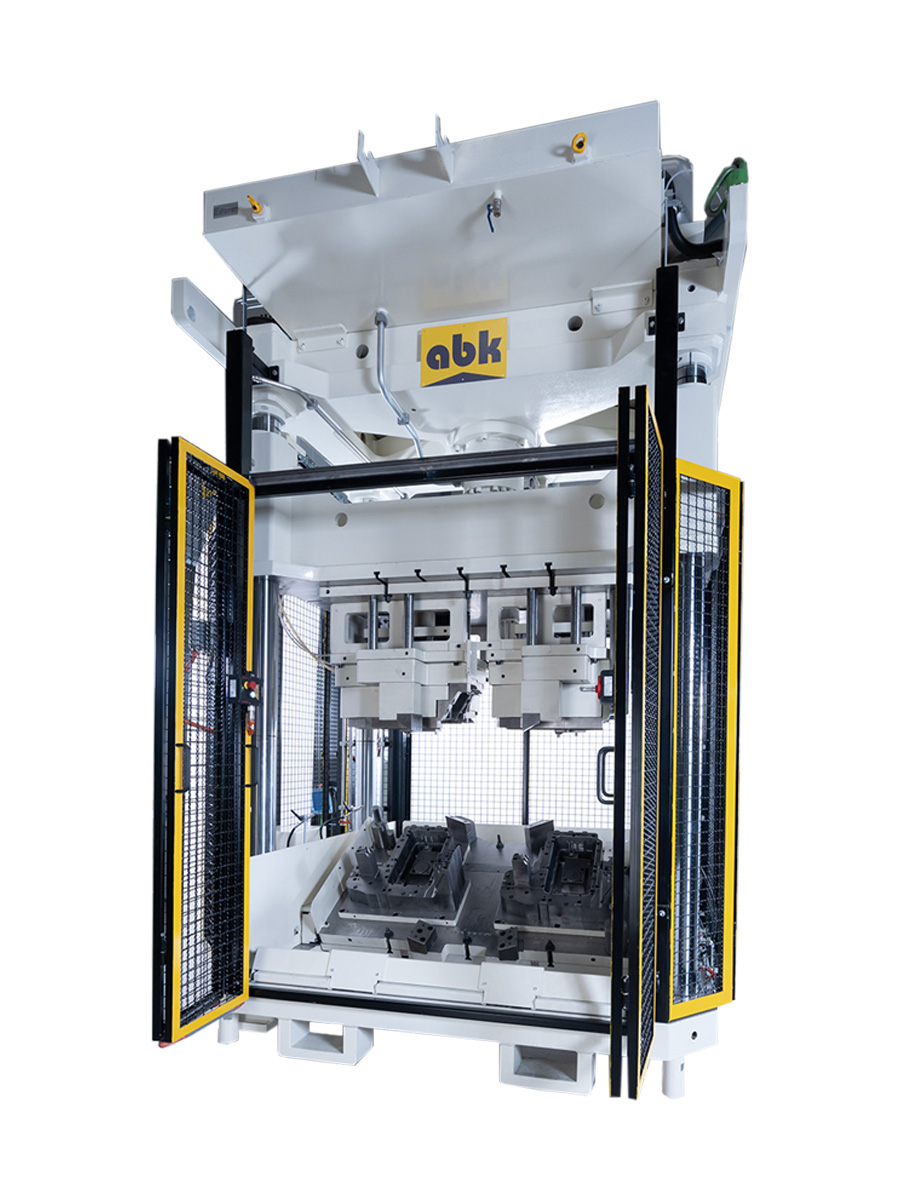

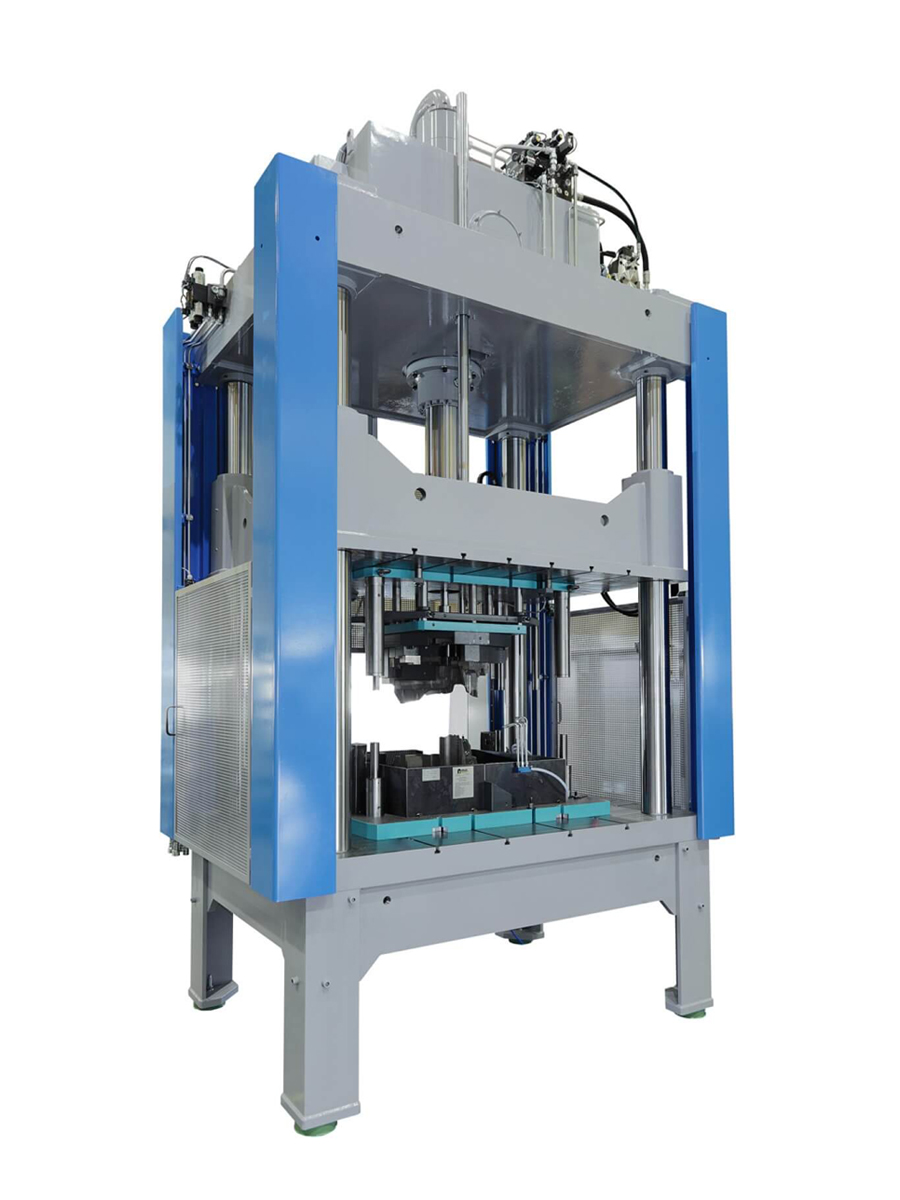

abk Pressenbau develops high-precision deburring presses and automation solutions for mega and giga casting applications. These casting processes enable the production of particularly large structural components – for example, for e-mobility and modern vehicle platforms. Our press systems are designed to be robust, highly durable, and optimized for fast cycle times. With in-house development of hydraulics, control systems, and software, we create individually adaptable solutions with maximum process reliability.

Mega casting brings new challenges – and we deliver the right solutions. Die-casting applications in the mega and giga casting sector make it possible to replace up to 100 individual parts with a single structural component. This significantly simplifies and accelerates production processes – while at the same time, the demands on deburring presses and tooling increase considerably.

abk Pressenbau develops highly specialized deburring presses with column openings of up to 3,000 × 2,500 mm and a pressing force of up to 600 tons – setting new standards and opening new paths in deburring technology.

The generous dimensions allow the use of tool carriers up to 3,600 × 3,200 mm and tool weights of up to 42 tons.

Such dimensions require well-thought-out overall concepts – from burr disposal and automatic clamping and holding systems to integrated tool change solutions.

Since manual tool changes are no longer feasible at this scale, we have developed a standardized, fully automatic change system – safe, fast, and already proven in comparable press systems.

For powerful and precise deburring of large structural components

Suitable for particularly large-volume aluminum die-cast components

For the use of heavy special tools in the casting sector

Fast and safe changeover – no manual operation required

Compatible with robots, conveying systems, and higher-level control systems

For maximum availability in continuous industrial operation

Simple and Efficient

Simple and Efficient

Simple and Efficient

Simple and Efficient

Simple and Efficient

Simple and Efficient