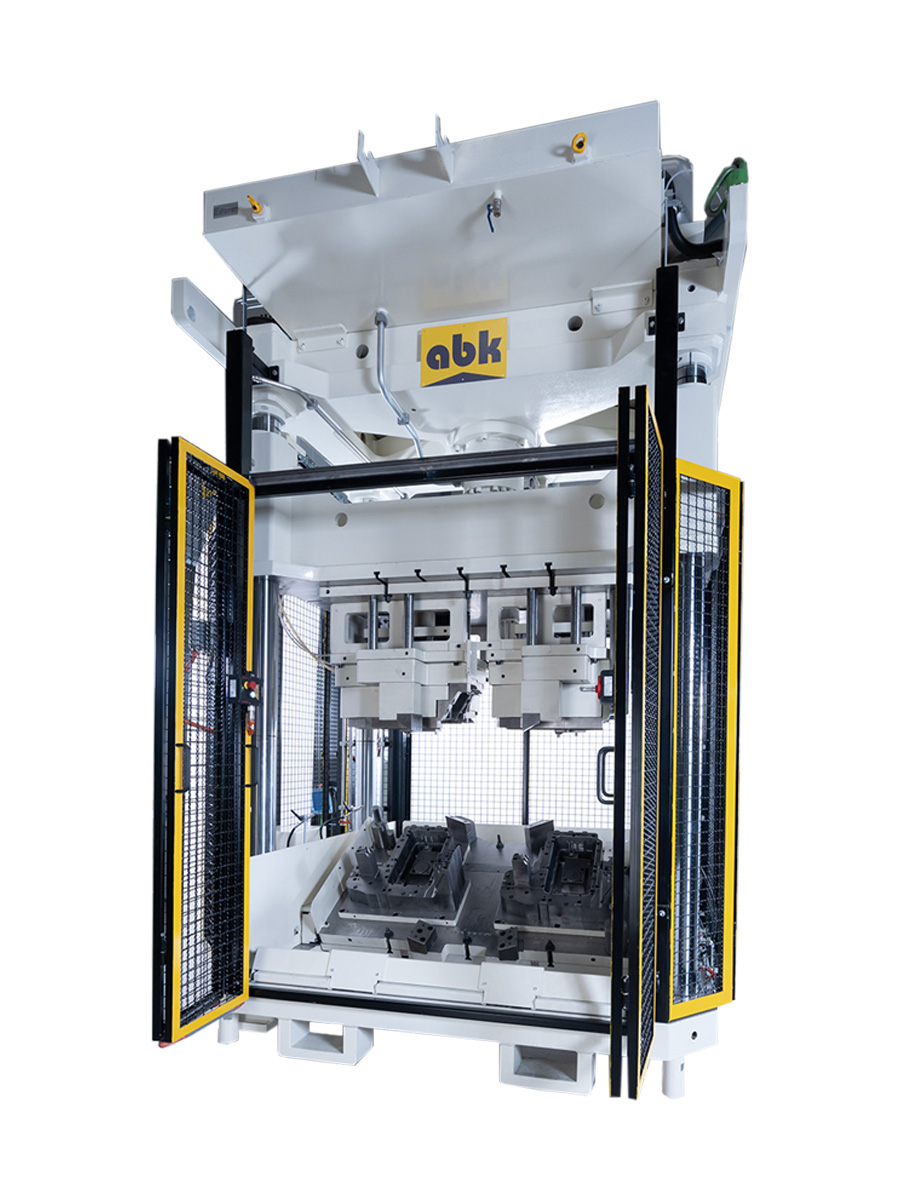

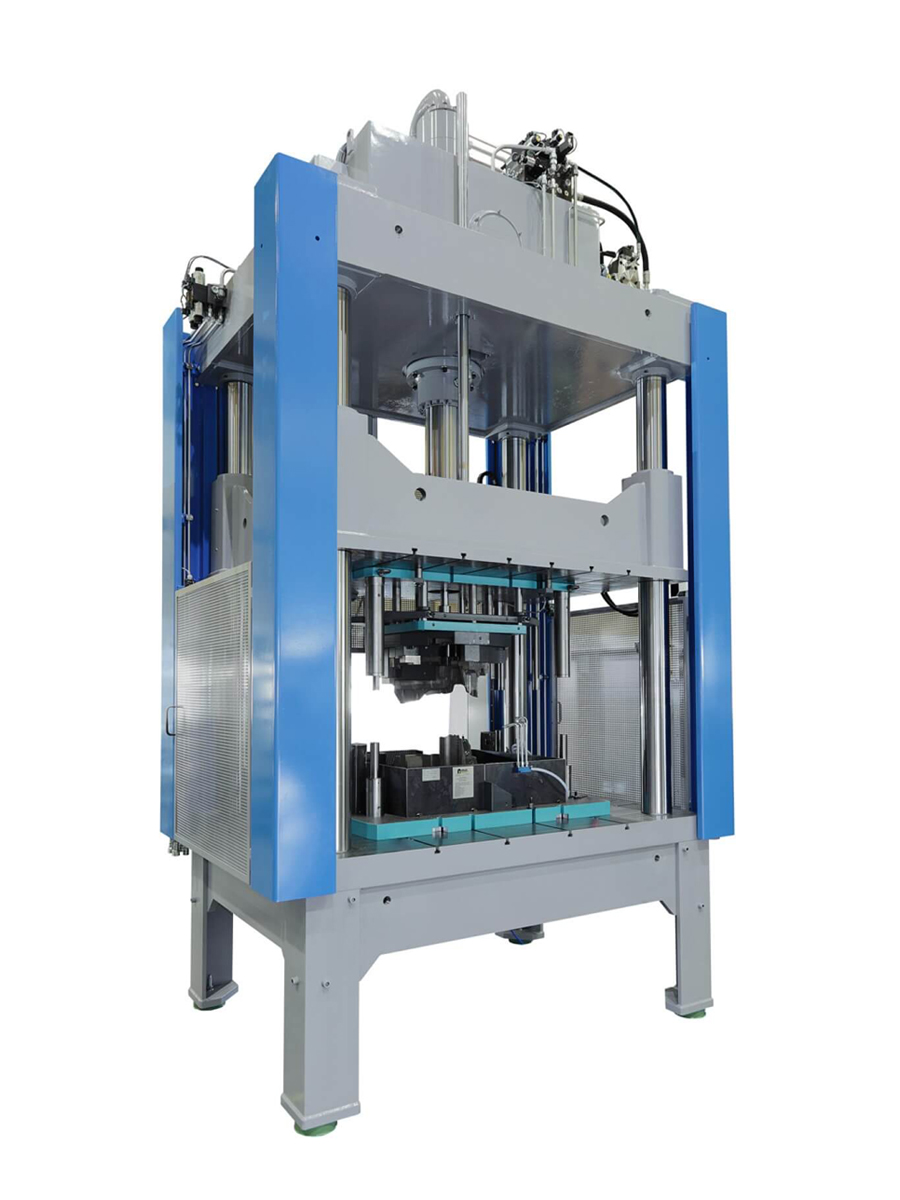

abk Pressenbau entwickelt hochpräzise Entgratpressen und Automatisierungslösungen für Mega- und Giga-Casting-Anwendungen. Diese Gießverfahren ermöglichen die Herstellung besonders großer Strukturbauteile – etwa für E-Mobilität und moderne Fahrzeugplattformen. Unsere Pressensysteme sind robust konstruiert, hochbelastbar und für schnelle Taktzeiten optimiert. Durch unsere interne Entwicklung in Hydraulik, Steuerung und Software entstehen individuell anpassbare Lösungen mit maximaler Prozesssicherheit.

Megacasting stellt neue Anforderungen – wir liefern die passenden Lösungen. Druckgusslösungen im Mega- und Gigacasting-Bereich ermöglichen es, bis zu 100 Einzelteile durch ein einziges Strukturbauteil zu ersetzen. Dadurch werden Produktionsprozesse deutlich vereinfacht und beschleunigt – gleichzeitig steigen die Anforderungen an Entgratpressen und Werkzeuge erheblich. abk Pressenbau entwickelt dafür hochspezialisierte Entgratpressen mit Säulendurchgängen bis 3.000 x 2.500 mm und einer Presskraft von bis zu 600 Tonnen – Maßstäbe, die neue Wege in der Entgratungstechnik eröffnen.

Die großzügigen Abmessungen erlauben den Einsatz von Werkzeugträgern bis 3.600 x 3.200 mm und Werkzeuggewichten bis 42 Tonnen.

Solche Dimensionen erfordern durchdachte Gesamtkonzepte: von der Abgratentsorgung über automatische Spann- und Niederhaltesysteme bis hin zu integrierten Werkzeugwechsellösungen. Da ein manueller Werkzeugwechsel bei dieser Größe nicht mehr möglich ist, haben wir eine standardisierte, vollautomatische Wechsellösung entwickelt – sicher, schnell und bereits in vergleichbaren Pressen erfolgreich im Einsatz.

Für kraftvolles, präzises Entgraten großer Strukturbauteile

Geeignet für besonders großvolumige Aluminiumgussbauteile

Für den Einsatz schwerer Spezialwerkzeuge im Gussbereich

Schneller und sicherer Wechsel – keine manuelle Bedienung notwendig

Anbindung an Roboter, Fördertechnik und Leitsysteme möglich

Für höchste Verfügbarkeit im industriellen Dauereinsatz

Einfach und Effizient

Einfach und Effizient

Einfach und Effizient

Einfach und Effizient

Einfach und Effizient

Einfach und Effizient